Pressure, P 1 (over pressure or absolute pressure).

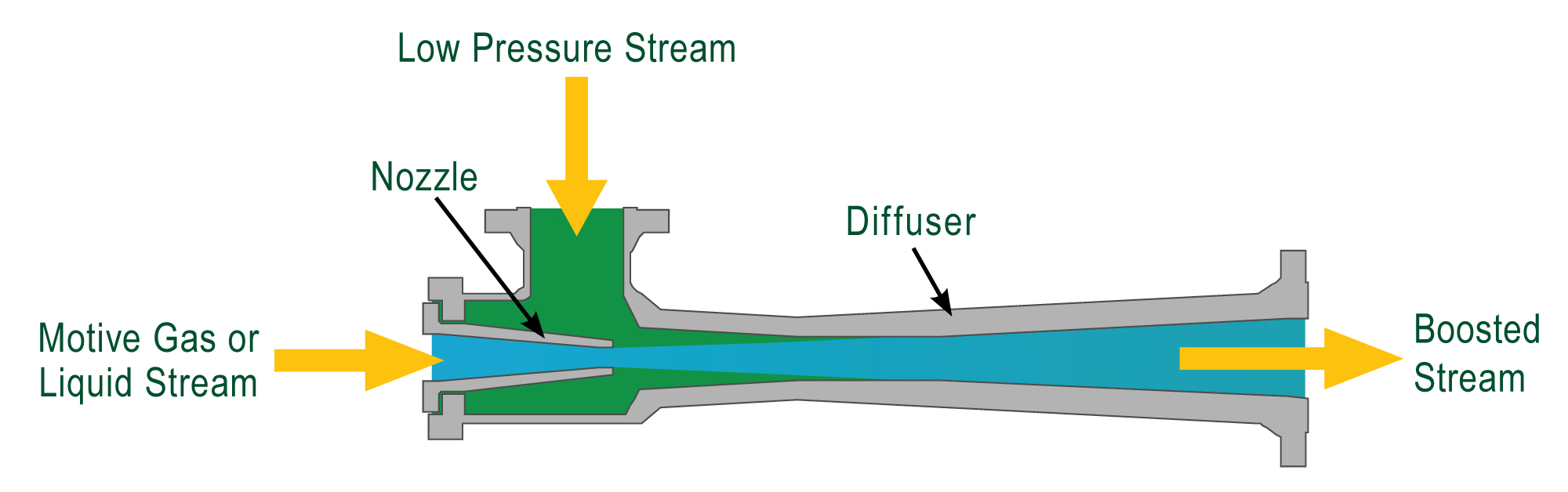

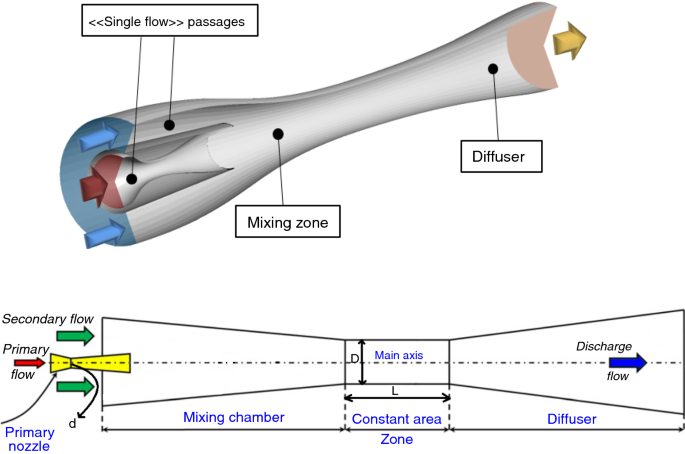

The suction medium passes through the suction nozzle, into the head of the jet pump. The flow rate at the discharge is the sum of the suction and motive flow rates: T he flow channel of the mixing nozzle consists of a part converging in the direction of the flow (the inlet cone), a cylindrical piece (the throat) and a diverging part (the outlet cone).Ĭonnection A for the motive medium with the highest pressure, P 1, and flow rate, M 1 Ĭonnection B for the suction medium with the lowest pressure, P 0, and flow rate, M 0 Ĭonnection C for the discharge of motive and suction media with a medium pressure, P, and flow rate, M We suggest you to read our catalog in order to become more familiar with our ejectors Here in Karajet we design all different types of Steam jet ejector, Gas jet ejector, Liquid jet ejector and Vacuum systems For our customers’ more convenience we offer online calculation service if you want to choose a steam jet ejector or vacuum ejector you can use our website to suggest us your project. Reduced and the pressure increased in a second nozzle. The result of this action is a mixture of the driving and entrained fluids, the velocity of which is t he practical application of this principle requires a simple apparatus, which normally consists of only three main parts: The principle of jet pumps is the entrainment and acceleration of the surrounding gas or liquid by the high velocity jet of motive liquid or gas emitted from the motive nozzle. ejectors can be useful in compressing the vapors and steamĮjector principle is that the vacuum ejector operates by the conversion of pressure energy into velocity in suitable nozzles. always remained the principle duty of these devices.between the different types of ejectors the vacuum ejector and the steam ejector are more useful in the petrochemical units and other related industries, however the jet ejectors are very similar to vacuum pumps and vacuum compressors but these jet ejectors have no moving parts so it makes them suitable for creating vacuum and also conveyance, mixing the gases also steam jet. Besides many other applications, however, generating vacuum has. Numerous options for the motive medium result in an exceptionally wide range of uses. Liquids, gases or vapours, rather than mechanical parts, serve as the motive medium.They are "Pumps without moving parts. " Jet pumps" or "vacuum ejectors" are devices for the conveyance, compression or mixing of gases, vapours, liquids or solids.

0 kommentar(er)

0 kommentar(er)